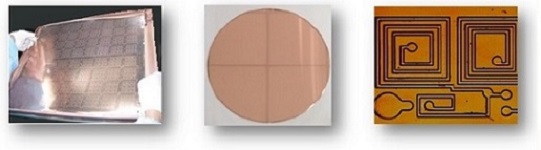

Ti-Cu Seed layer In line Vacuum Sputtering Equipment

Product Description

Advanced packaging process:

- UBM(Under Bump Metallurgy)

- RDL(Redistribution Layer)

- Sputter Ti/Cu seed layer

Equipment characteristic

- Low temperature sputtering process

- Low output time/high capacity design

- Good sidewall coverage

- Good film adhesion

- Vehicle automatic return system

Product application category

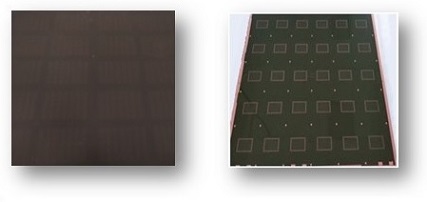

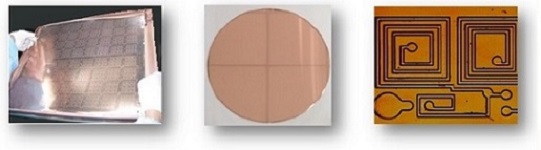

Non Plating Line

Product Description

- Inline Sputter system

- Non Plating Line

- Coreless Substrate

Equipment characteristic

- InLine High THP

- Low cost

- Good uniformity、reproducibility

- Link automatic retractable board machine

- environmental friendly,energy saving

Product application category

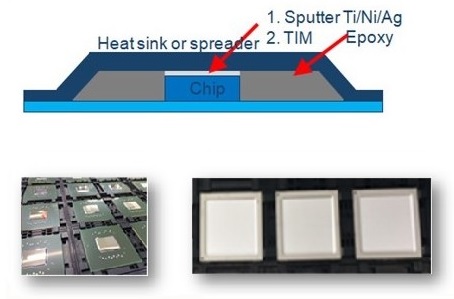

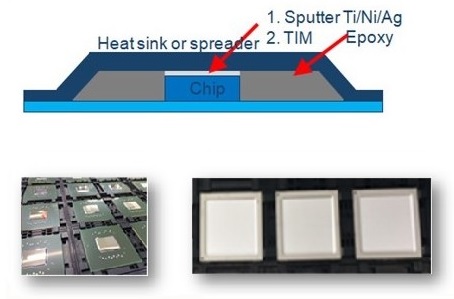

High heat dissipation film_Nano silver sputtering

Product Description

- Inline Sputter system

- Multilayer metal structure

- Alloy strong adhesion effect (nano silver)

- Alloy heat conduction effect

Equipment characteristic

- Low temperature sputtering process

- Low output time/high capacity design

- Good partial coverage

- Good film adhesion

- Vehicle automatic reflux system

Product application category

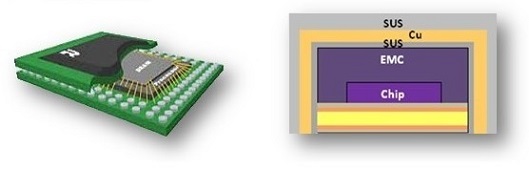

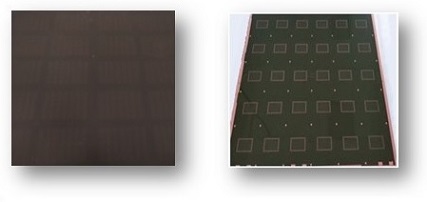

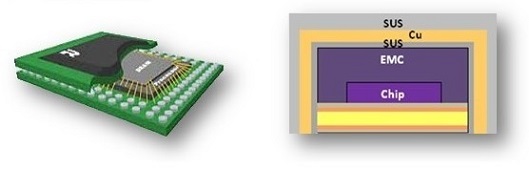

Horizontal continuous EMI sputtering equipment

Product Description

- Inline Sputter system

- SIP EMI

- Thick film process(>5um)

Equipment characteristic

- High heat dissipation technology

low temperature sputtering process

- Low output time/high capacity design

- Good partial coverage

- Good film adhesion

- Vehicle automatic reflux system

- High coating quality

Product application category

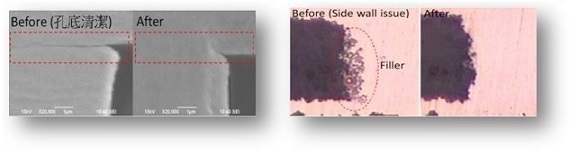

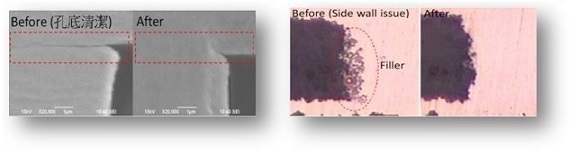

Vertical plasma etching equipment

Product Description

- Vertical Plasma Etch Equipment(Inline system)

- Plasma Desmear-Plasma Via Desmear

- Plasma Descum-Dry Film Descum

Equipment characteristic

- PCB Substrate warpage suppression function

- Low temperature process,no uncleanness

- RF Anisotropic etching to overcome the problem of hole expansion

- Even gas distribution,good etching uniformity

- Clamping of ineffective areas on the periphery of the substrate

- Graphics capabilities L/S < 2um,Via< 30um

Product application category

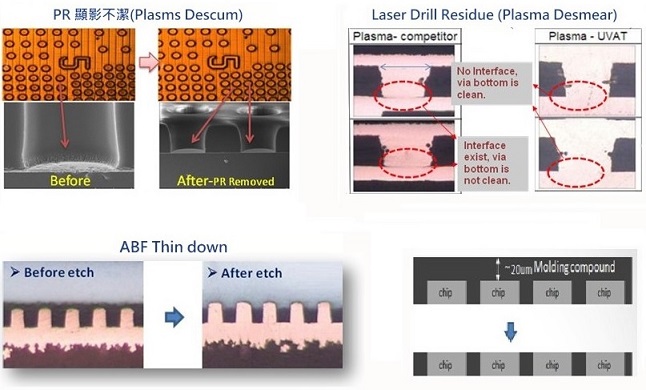

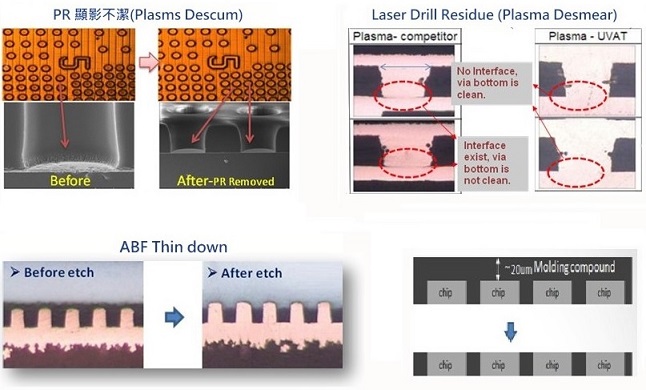

Horizontal Plasma Etch Equipment

Product Description

- Horizontal Plasma Etch Equipment

- Plasma Dry Etch

-Dielectric Etch

-Plasma Metal Etch

-Fine line Etch

- Plasma Thin down

-Plasma ABF Etching

-Plasma EMC Etching

-Molding Compound Etching

- Plasma Desmear

-Plasma Via Desmear

- Plasma Descum

-Dry Film Descum

- Plasma Pre-treatment

-Contact Angle

-Wetting

Equipment characteristic

- High-speed dry etching process

- High etching uniformity

- Modular design to achieve low cost/low footprint

- Advanced packaging(Panel Fan-Out FOPLP/FOWLP)

- High-end carrier board application technology

- With semiconductor-grade EFEM configuration

Product application category

Vacuum Oven

Product Description

- Vacuum Oven

- Vacuum Degas

- Deep water vapor removal

- Material Curing

- Anti-oxidation

- Residual Gas Analyzer

Equipment characteristic

- Deep water and oxygen remove

- Multi-chip heating at the same time,high-capacity systematic design

- High uniform temperature design to avoid substrate stress warping

- Temperature and time may depend on parameter stylization control

- Immediate or end point residual water、oxygen value detection

- Foundation plate size and piece number customized according to needs

Product application category